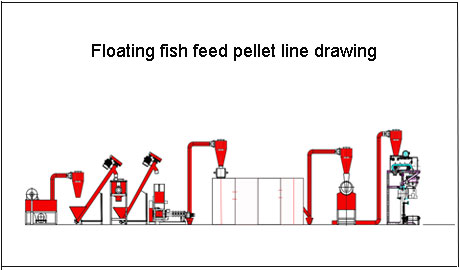

| Fish Feed Producing Line | ||||

| No. | Machine Name | Quantity | Specification | Picture |

| 101 | Crusher and Mixer machine(U-shape) | *1 | Power:3KW |  |

| Power:4KW Output:250kg/10-15min |

||||

| 102 | Screw conveyor | *3 | Power:2.2kw |  |

| Capacity:1000-1500kg/h | ||||

| Size:4000*550*750mm | ||||

| Weight:115kg | ||||

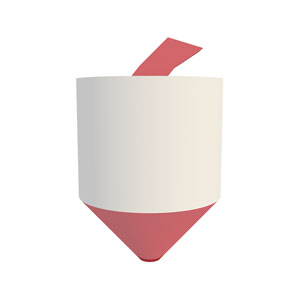

| 103 | Buffer bin | *1 | Capacity:2m³ |  |

| Size:1500*1500*1800 | ||||

| Weight:220kg | ||||

| 104 | Dry Type Feed Extruder | *1 | Main motor power: 75kw |  |

| Feed motor power: 1.1kw | ||||

| Production: 1000-1200kg/h | ||||

| Cutting motor power: 2.2kw | ||||

| Dimensions: 2750*1980*1800mm | ||||

| Weight: 2000kg | ||||

| 105 | Air blower with pipe | *3 | Fan power: 3.0kw | .jpg) |

| Unloader power: 1.1kw | ||||

| Production: 1000-2000kg/h | ||||

| Dimensions: 2200*750*2700mm | ||||

| Weight: 220kg | ||||

| 106 | Feed Drying Machine | *1 | Mesh belt motor power: 5.5kw |  |

| Feed motor power: 0.75kw | ||||

| Exhaust fan power: 1.1kw | ||||

| Circulating fan power: 0.55kw | ||||

| Required steam quantity: 0.2-0.3MPa | ||||

| Production: 1000-1500kg/h | ||||

| Dimensions: 5850*1600*2400mm | ||||

| Required steam quantity: 0.5t/h | ||||

| Weight: 2200kg | ||||

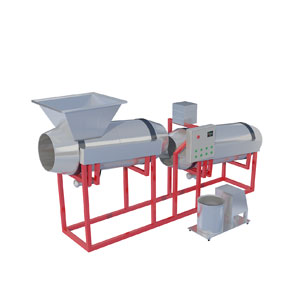

| 107 | Drum sprayer | *1 | Host power: 1.1kw |  |

| Oil pump power: 0.55kw | ||||

| Oil drum heating power: 1.5kw | ||||

| Production: 1000-2000kg/h | ||||

| Dimensions: 5000*800*1550mm | ||||

| Weight: 380kg | ||||

| 108 | Feed Cooling Machine | *1 | Fan power: 4.0kw |  |

| Shakron unloader power: 0.75kw | ||||

| The discharge method is pneumatic discharge | ||||

| Production: 1000-2000kg/h | ||||

| Dimensions: 1800*1500*2400mm | ||||

| Weight: 980kg | ||||

| 109 | Electrical control system | *1 | ||